|

The Early Days... |

|||

|

Phoenix Air Defense Sector Click photo for larger view! Commander Colonel William R Nevitt |

|||

|

Oct. 22, 1959 orders ) a teletype or com. center message?) moving Capt. Shumake from Yuma Air Station and to have him report to command the 4629 support squadron at PHADS |

Activation of the 4629th Support Squadron, commanded by Captian James Shumake

|

||

|

Letter of appreciation to Captain Shumake from Systems Development Corporation. |

|||

|

|

|||

|

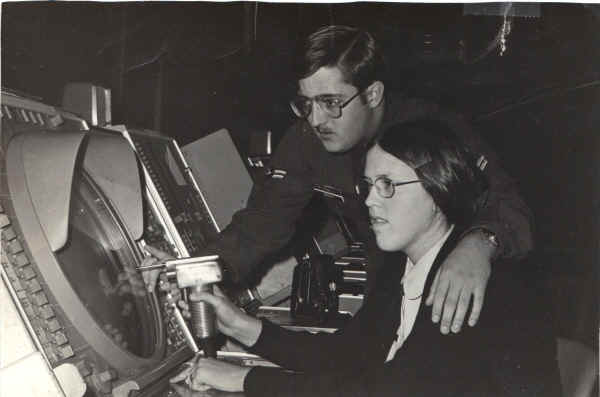

Airman First Class Trent Bailey, Weapons Controller Technician at 26th NORAD Region/Air Division

(click SAGE artwork to open in a separate large window)

"Airman First Class

Trent Bailey, Weapons Controller Technician at 26th NORAD Region/Air

Division points out a target for Airman Toni Bailey, a Air Surveillance

Operator new to SAGE Operations, who is also his spouse." Picture was

taken on February 12th, 1975 for an article in the Division's newsletter.

As I recall, there were 3 couples that worked together in the 26th Air

Division and two of them were stationed at the NORAD Region Control Center

at Luke AFB, AZ. Trent Bailey tells us "The 26AD

crest is actually printed on adhesive-backed paper and was used to mark

manuals, books, etc. I remember a sheet of them had a

huge one, like 8X10, then smaller ones, down to an inch high.

This is an 3" original from there, and I've had it since my days

there. Yellowed with age, it is stuck to a mirror on my

workstation at home."

|

|||

|

By 1st Lt. Gregoire M. Stanek - (From

STAGECOACH June 30,1972) - Photos by A1C Paul Smith SSGT. DAVID LAZOK and CMSgt. Ben Greene check out the IBM 718 printer. - SSGT. KENNETH WHITE: and SSgt. Ronald Kareiva make a daily check on a magnetic drum.

SSgt. JAMBS THOMAS makes some switch settings on the Computer maintenance console. SSGT. DAVID LAZOK works on the IBM 718 printer.

SGT. ROYAL PRENTICE performs a check on a Plugable Unit in the maintenance and test lab of the computer complex. |

|||

| The "OMEGA" The end of CLYDE at Luke Air Force Base - 26AD |

|||

|

October 20, 2006 Subject: Removal of AN/FSQ7, 26 AD, in Feb 1984 (click above for LARGE photo in a new window!)

I was an Electronics Installation Team Chief, working for USAF out of Norton AFB, CA and assigned to the 1835 EIS (Electronics Installation Squadron). One of my assignments was to Luke AFB, AZ to remove (scrap) the AN/FSQ7 computer from the SAGE building. At some point I was told that it was the last active FSQ7 in the Air Force inventory; but I never had proof of this fact. We scheduled our arrival only after extensive prep work was done to turn off the power sources to the equipment and the equipment had been harvested for precious metals. All we really had to do, as I recall, was to cut away all connectors and unbolt the major components and take them out of the structure. The first week we ripped into it. I mean, we got permission to disassemble 14inch metal chop saws from the stands and use them “free-hand” to cut the 4inch armored power cables from up in the cable racks. The overhead cable racks themselves were the most extensive I had encountered to that time, with three levels of racking. We were flying around like monkeys up in those racks. We would cut a cable at a strategic point where it ran down some racking for perhaps 100 feet. Where the cable dropped to floor level a couple team members would pull on it and the steel cable cover would start to slide over the racking. Slowly it would pick up speed. The weight of the cable would cause it to keep accelerating until it shot out of the rack and hit the floor with a boom! That was lots of fun. The cut pieces could then be maneuvered into metal mini dumpsters where a forklift would pick it up and haul it out to the parking lot. I got some ideas for a comic while this was unfolding. The parking lot out back was where everything ended up. That’s when I saw these trays of ferrite memory . They were either nine or 16 panels to a tray. Anyways, I asked for permission to keep one or two of the trays, as I could see that the panels could be separated and would make interesting souvenirs for my team (any one who wanted one). We did the job in record time. I took black and white photos so that the base paper at Norton AFB could publish an article. I had the byline. I remembered the article because it used my picture of our team member sawing through the cables with that 14inch metal chop saw, full face shield and sparks flying! In the group picture, if enlarged, you can clearly see the racks of computer parts with the cables cut off at the top behind the group. Back at Norton AFB, I desoldered the individual memory plates from the flat plane that held them. Then I poured some art epoxy that is used to cover wood tables inside of the delicate ferrite bead weaving. When it set up you could see all the beads and wires, and didn’t have to worry about breaking the hair-like wire and bead assembly. I also drew a cartoon to remember our escapade. Somehow, I knew this was a special TDY assignment. For what it is worth, I have scanned the comic, two photos, and the letter from the commander, Det 2, 26 AD. Note that the new 26 AD had been moved to March AFB, CA by this time. (click above for LARGE photo in a new window!) Stephen E. Engberg MSgt, USAF Retired

Ref: Proposed revision to service request Brian Wilson needs to modify our current service request being used. a. They are adding a box for tax status. b. adding a box for additional technician. My first recommendation is delete the parts block and utilize this space for work performed/parts used. 2nd recommendation is that a maximum of two additional techs should suffice; I think four is a waster of space. Please put your two cents in; Brian Wilson TSM would like to know; even if you like it as it stands. Stephen E. Engberg October 20, 2006 To: techs Ref: Proposed revision to service request Brian Wilson needs to modify our current service request being used. a. They are adding a box for tax status. b. adding a box for additional technician. My first recommendation is delete the parts block and utilize this space for work performed/parts used. 2nd recommendation is that a maximum of two additional techs should suffice; I think four is a waster of space. Please put your two cents in; Brian Wilson TSM would like to know; even if you like it as it stands. Stephen E. Engberg

|

|||

|

|||

|

|||