|

SAGE A/N FSQ-7 NORAD Computer |

|||

|

|

Click to see an awesome IBM logic trainer and also a pull drawer from A/N FSQ-7 SAGE Computer!---------> |

|

|

|

Can anyone tell us about |

|||

|

David Scully worked as a programmer at System Development Corporation on the SAGE system starting in 1962. He has sent us several of the "green books", the specifications for the AN/FSQ-7 and some of its components in various configurations. We are happy to add these to the Archives here..

Pete Karculias was an electronic technician/computer repairman for the

Q-7 back in

|

|||

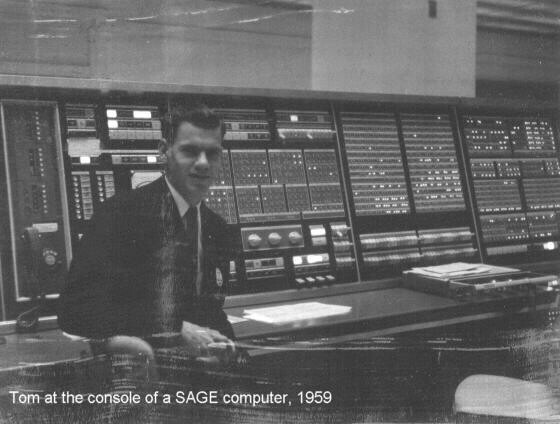

Introduction. These are personal photos of the 25th Air Division HQ SAGE system. They were taken in the spring of 1969 in the evening. I could not photograph the operators on duty as it would have interfered with their duties. Also, some areas were off limits due to security (ECM room, e.g.). 1. A_computer.jpg Duplex Maintenance Console. This is the main control panel for computer operation. The large box in the foreground is a line printer. 2. B_computer.jpg The Duplex Maintenace Console for computer B. Part of the Long Range Inputs Console is in the left background. Magnetic tape drives can be seen in the right background. 3. Big_Mem.jpg Magnetic Core Memory No. 1. This is a 256 x 256 array of 33-bit words (total 65,536 words). Memory cycle time was about 3.25 microseconds. Actual operational time 6 microseconds. Memory devices are iron ferrite cores. 4. CP_Console.jpg This is the Air Division Commander's console in the Command Post of the Direction Center. 5. CP_Console_Close.jpg Close-up of the Digital Display of the Commander's console. The command post consoles did not have the large situation displays found elsewhere. They used a large projection system to display the air situation on a central screen (this was not used except in an alert and so was not on when the photos were taken). The process used was to snap periodic photos of the situation display using a special blue-light console, develop the film and project it. So the projection display was always behind real-time by the film processing time (< 1 minute). 6. DC_Command_Post.jpg This is the Command Post in the heart of the Direction Center. 7. Display_routing.jpg Actually this is the Manual Inputs Frame. This is the variable wiring side. Wires can be relocated to move signals to and from different consoles. This provides system reconfiguration capability. 8. Display_routing_2.jpg This is the "permanent" side of the Manual Inputs Frame. Signals from various system components arrive on this side and are routed to their destination on the other (variable) side. 9. Drum_1.jpg A magnetic drum assembly shown in position for maintenance access. 10. Drum_2.jpg Another view of a magnetic drum in maintenance position. Technical information I recall: Each computer had 12 drums. Six were for the display system and six for central computer use. Each drum had fixed position read/write heads - at least 33 plus some spares. A word was 33-bits so you could read a word by reading all heads at the same time. The system had to deal with addressing by computing the angular displacement and timing the operation so the right data was under the heads. I don't recall the capacity but it was on the order of K words! The Central Computer stored it's system subroutines on drums and loaded them when needed. 11. Its_Crashed.jpg This is for fun. We kept a Polaroid camera in the operator's room to snapshot the console if a computer crahsed. We could reboot and analyze the status later. I am on the right. The computer has just crashed with a memory parity error. 12. Large_frame.jpg This is the Situation Display Generating Element (SDGE). It processes information stored on the magnetic drums to generate the Situation Displays (SD) for over 100 SD consoles. 13. Lil_Mem.jpg This is core memory No. 2. It has a 64 x 64 array of 33-bit words for 4096 total. It has the same operating speeds as Memory No. 1. The real reason there were two cores was to allow one memory to run diagnostic software on the other. There was also something called Test Memory. This was an early equivalent to ROM. There was a patch panel that could be installed in the maintenance console. It was hard-wired to logic 0 and 1 levels and was the first 32 words of the address space. We kept a bootstrap loader in it that would reload the system from tape. We also had different panels for maintenance programs. You can see three of them in the B-Computer.jpg photo. Just to the left of them is the pull-out slot they go into. 14. Lil_Mem_Close.jpg Close up of core memory 2 showing the X and Y plane drivers and individual iron ferrite cores. 15. Long_View.jpg This shot shows the wall-to-wall distance of the area occupied by one computer. Each computer occupied approximately a square of this size. 16. LRI_frame.jpg This is the "tube-side" of the Long Range Inputs Frame. 17. Mag_Drum_Frame This is a Magentic Drum Storage Frame. It housed six drums and their control circuitry. There were two such frames for each computer. 18. Op_Console.jpg This is the computer operator's console (left). This is in the same room as the Maintenance Consoles. It includes a Situation Display (SD) a 19 inch CRT, a Digital Display (DD), a 5 inch CRT. Also there is a push-button panel which controls SD and DD information. On the right are the Duplex Switching Consoles. These provide switching functions to make either A or B computer "Active". One computer was always active and the other standby. If the standby computer was running the standby Air Defense program (rather than maintenance) the system was in "Full Duplex" mode. If the Active crashed, switchover could be done in a couple of seconds. In Full Duplex Mode, the Standby computer received periodic data transfers from the Active so it was "ready to go" if needed. 19. Pwr_Control.jpg This is a panel on the power control system. The power plant (we had our own) generated a million watts for the computers. We also had our own air-conditioning system. Chilled air was pumped through the consoles at the bottom and out the top. The exhaust air was warmed by the frames and was recycled to heat the building in cool weather. If air conditioning failed, an extremely loud klaxon over the operator's station (you can see it to the right on the wall in Op_Console.jpg) would go off. The operator immediately called the power house. If AC could not be restored in 60 seconds, an emergency power down was done. The reason was that the magnetic core memories would begin to melt down if left without cooling air for much longer than that. It went off once while I was on duty. It turned out to be a false alarm though. 20 SID_Close.jpg Close-up of a Situation Display (SD) console. You can see the outline of Washington, Vancouver Island and British Columbia, Canada to the North. The 25th Air Division covered all this territory. Each Direction Center (DC) overlapped coverage with the adjacent DCs. The DC to the South was located in California. When it was shut down, parts of the machine were sold to a Hollywood movie company. For many years later, we saw them in movies and TV shows, wired up to make the lights blink and flash. Most notable were the Voyage to the Bottom of the Sea (the TV series) and the "Kellog Computer" commercial which spewed cereal boxes out of the test memory door! 21. SID_Console.jpg This is longer shot of the SD console. 22. Simplex.jpg This console provided operation and maintenance of the Long Range Inputs and Outputs. Simplex because there was no redundant hardware. Each radar station fed digitized data to the DC over public telephone lines (a first - they had to invent the modem!). The DC also sent data to the neighboring DCs and to the Command Center (the AN-FSQ-8 computer). 23. Status_Board.jpg This is located in the command post. It provided Air Division Status data to the commanders. It was updated by the WW II method of guys writing backwards on the back of the Plexiglas. |

|||

|

|||

Two Tags off 'Clyde' the AN/FSQ-7 Outside Luke AFB Given to me back in

the 80's |

|||

|

Sage Logistics Handbook from March 1960. This copy

belonged to 26AD At Luke AFB. |

|||

|

Nice general NORAD Brochure |

|||

|

26AD Cap, Hard to do this in a scanner folks! |

|||

|

October 15, 1997 Bunny

White Archivist

– Lucent Technology 600

Mt. Avenue Rm

3A-302 Murray

Hill, NJ - 07974 Bunny, Attached

is a map showing the principal installations of the SAGE System

(Semi-Automatic Ground Environment ) a USAF/RCAF project that

comprised much of NORAD’s air defense of the US and southern Canada back

in the late 50’s through the early 80’s. Interceptor air bases of the

Air Force and Navy are not all shown. The

NIKE anti-aircraft systems, Ajax and Hercules, (the Army’s systems

designed and built by Bell Labs and Western Electric) was integrated with

this system. NIKE locations are not shown. This

system was significant in many ways: 1.

It was the first big integrated communications network.

High speed data ran at 1300 BPS on the 1A Digital Signaling System between

the worlds largest vacuum tube computers (AN/FSQ 7s and 8s) which were

duplexed for reliability at 23 direction centers (sectors). The sectors

were fed radar data from apx. 250 radar sites, Texas Towers, picket ships,

airborne radar, and weather stations. The 23 sectors fed summarized track

data to seven regional combat centers, in turn to the NORAD center at

Colorado Springs. 2.

It gave the computer industry a big boost.

The IBM 7090 was essentially a solid state version of the AN/FSQ 7/8 which

was also converted. Burroughs also had a pre-processor at the radar sites. 3.

The first ground control of interceptor aircraft was carried out by this

system.

Ground to air radio provided digital vectoring of the aircraft to the

pilot via a fire control CRT on the aircraft.

A wide variety of jet aircraft and air to air missiles were used. 4.

Digital Display Technology was promoted.

Light pens, random access digital display CRTs were developed by Hazeltine

and IBM and used by the thousands in this system. 5.

Simulation of hostile aircraft was developed by WE during the

implementation of the system. This

was done to cut down the use of large aircraft as targets during training

exercises, and system integration testing of ground to air radio and

interceptors.

(Live aircraft were used in the final system tests but not actually

shot down.) 6.

The first in line microfilm fast processed 35 mm projection displays

were incorporated. These preceded the

printer plotters that followed in the 60s and 70s and were able to project

a large screen display within 30 seconds of the computer generated

display. 7.

WE was able to obtain a

large number of computer trained personnel. At a

time when very few computer trained people existed, close to 500 engineers

and technicians were trained at MIT’s Lincoln Labs in digital

techniques, computer programming and radar and other systems integration

areas. These people often formed the cadres of computer personnel at many

locations and other projects throughout the company when the SAGE

implementation phase ended in the 1962-3 period. Although

the SAGE system design was led by the MITRE Corporation, Western

Electric’s Air Defense Engineering Service (ADES), headquartered on

Church Street NYC, was awarded the systems integration contract to

coordinate the installation, and perform the subsystems and systems tests.

(The good work on the DEW Line around the Arctic Circle helped getting the

award.) It checked out hardware and software of many subcontractors (IBM,

Borroughs, RAND/SDC, GE, Philco, Raytheon and others including

AT&T ) WE

hiring started in 1955 and hit full stride in 1957 with training started

at Murphy Army Hospital in Boston and then moved to MIT Lincoln Labs,

Lexington MA. Class groups of about 15 started about every three weeks.

Training lasted nine months for the first three years, afterwards which,

with trained people in the field, it was cut to six. Students were paid a

base salary but not paid expenses until they went to the field and were

expected to find their own housing with many going to boarding houses and

apartments in Cambridge. Upon

graduation they were assigned to one of five field test teams that would

move about every nine months if the sector tests went well. The first five

sectors to be checked out were on the East Coast.

Test teams were comprised of about 50 to 65 persons; half at the

direction center, half at the radar and ground to air radio sites. At the

end of a sector about ten persons were left behind to handle retrofit

changes and upgrades. The others would be split into two groups with half

matching up with half of another group at a new sector; the other half

with another at another new location. Retrofit personnel losses were

replaced with “rookies” just out of school. (The old men were those

with two or three year’s experience.) It made for close friendships

between couples that shared the hardships of the road, moving and looking

for a new place every nine months.. Essentially your company work mates

and their spouses were your family. Those friendships lasted for many

decades after the project winded down. The

first sector (New York Air Defense Sector) was cut over in late 1958. The

entire 23 SAGE sector and 7 combat center job was completed in 1962 (on

time) with smaller scale retrofits taking place for a few more years. A

few of the experienced people went to Bell Labs Whippany where they worked

on a series of very involved tests of SAGE and NIKE Hercules air defense

effectiveness in 1961-62. An experimental SAGE system was maintained in

Montgomery, AL for testing of new sub-systems through the 60’s. In

the early 60’s, some of the personnel of WE ADES were phased into Bell

labs/WE projects such as MAR-I, NIKE X/Safeguard, Underwater Defense, and

ESS. Some went to WE factory or service locations, Bell operating

companies and AT&T. Many, longing to be closer to home, now with

children, or seeking another venue went with NASA, Jet Propulsion Labs, or

other companies. SAGE

was a great project for the country, the company, and most of the people

who worked on it. For many it was a way of learning a new field, getting

to see the country, and make a few dollars in the process, - a great

adventure which led to many good things.

|

|||

|

Attached is a diagnostic that was run on the

switching console. Circa 1958 at first the blue suit site Ft Lee VA. I

was in first class to go through Kingston, NY.

Tip

|

|||

|

|

|||

|

Ed, |

|||

|

|

|||

|

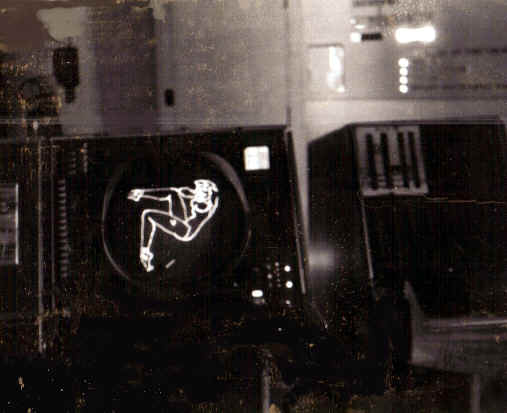

The

Last of the SAGE Techs I arrived at McChord AFB in Tacoma, WA, in January of 1983, after finishing tech school at Keesler AFB in Biloxi, MS. At Keesler, the systems we trained on seemed a bit behind the times, including the BUIC (BackUp Interceptor Control), based on the Burroughs D825. I figured though, that once I reached my permanent duty assignment, I'd get to work on some more modern equipment. When I received my assignment, I was quite distressed to discover that I'd be working on the AN/FSQ-7 and its 50,000 vacuum tubes, installed in 1958! McChords' Q7 was nearing the end of its service life, and I found myself in the last group of technicians to be trained and qualified on the Q7. Things weren't as bad as I anticipated, though, and I was eventually selected for one of the four remaining maintenance slots on the new system, the AN/FYQ-93 (ROCC). I spent 8 months working on the Q7, before heading for Tyndall AFB in Panama City, FL for training on the new system. Working on the Q7 turned out to be an interesting experience. A computer big enough to walk around in! I trained under TSgt Larry White, in Central Computer (CC). We were short handed on the Q7 because most of the techs had been moved over to the new system (ROCC), but we still had to keep the Q7 running. I completed OJT training on the Q7 in record time, and was soon working shifts as a qualified CC troop. The final part of Larry's training program involved pulling a random tube from the standby system, and having me deduce its location using the Duplex Maintenance Console (DMC) and available diagnostic procedures. Some of the maintenance procedures were particularly memorable, such as changing heads on the drums. Because it took in excess of 20 minutes for a drum to spin down, you couldn't often afford the down time and you changed the head while the drum was turning at speed. It was a nerve wracking process which involved using an oscilloscope to monitor the signal amplitude on the head. You cranked the head down towards the drum surface until the signal reach the proper level. If the head went too far and actually touched the surface of the drum, it would score the surface and make that track unusable. At least one of our female techs refused to change heads on a live drum, after qualification. Running "margins" on the system meant using the Marginal Checking System to help detect system components, especially tubes, which were weakening and about to fail. Voltages were varied by small amounts to specific parts of the system, while running diagnostic programs to check for errors. It was also used to keep the core memory systems in adjustment. I still have a printout which lists the ideal readings for margins on Big Mem. Adjusting Big Mem meant using a flat blade screwdriver to make minuscule adjustments to a pot with a quarter inch shaft. A tiny tap was all it took to bring it in or out of adjustment. One of the annual maintenance procedures involved powering down one of the duplexed systems. For the annual PMIs (Preventive Maintenance Inspection), all of the available techs would be called in to help with this all day project. One of the jobs was inspecting the power supply units for defective selenium rectifiers and electrolytic capacitors, and replacing them. The capacitors were installed in "cap trays", with metal bus bars connecting the capacitors, and a neon indicator on the front which would indicate a problem with that tray. With the power off, you had to discharge the cap trays with a special tool that looked like a gigantic, two pronged plug. There was a lot of power stored in those units, and I never liked working around them. Bringing the system back up after a power down was an adventure, since something would invariably fail when power was applied. On the lighter side, programmers over the years had written some interesting "diagnostic" programs for the system. One was the Hula Girl, which was an animated drawing of a hula girl on the display scope. If you pointed the light gun at her navel and pulled the trigger, her skirt would fall off! Another was an interactive game of baseball, played on the display scope by two players. A baseball diamond was drawn, with some crude base runners. One player would press a button on the scope to pitch the ball, and the other would press a button on a cord attached to the scope to swing. If the batter connected, the men would advance around the bases. One night, after the PMIs were completed, two of our techs were playing baseball on the standby system's maintenance scope. The red phone rang, which was connected to the Senior Director (SD) upstairs in the display room. Expecting a problem, one of the techs answered the phone, to hear the SD ask, "Who's winning?" Apparently, one of the display operators had switched over to the standby system and saw the game in progress. Fortunately, the SD had a sense of humor. There were also programs written to play music on the Q7. The DMC had a speaker on it, with a volume control and a switch to select one of four register bits to monitor. During normal air defense operation, the speaker was usually turned to a low level to monitor the operation of the system. The air defense program had a certain rhythm to it while cycling normally, and an experienced tech could often catch a problem early by hearing a change in the pattern. In standby mode, by toggling the register bit on and off at a defined rate, you could produce definite musical pitches through the speaker. The problem with the existing music programs was that it was a complicated process to write a program to play a tune, and each program could only play one tune. Over the course of several mid-shifts, I wrote a music interpreter, which would read a short data deck (punch cards) telling which notes to play and for how long, making it easy to program new tunes. After one productive mid-shift, the day crew arrived to hear the standby system playing "The Liberty Bell" march, with big block letters on the display scope spelling out "Monty Python's Flying Circus". I wish I had saved that program! When McChord's Q7 was dismantled in 1983 after 25 years of operation, the crew saved a couple of pieces for me: a switch/indicator assembly from the DMC and a 64Kbit core plane from Big Mem. I've also acquired a few other parts over the years, including two PUs, some panel faceplates and a LRI test panel assembly. I have a page dedicated to my SAGE artifacts, here: http://ripsaw.cac.psu.edu/~mloewen/Oldtech/SAGE/ Most people don't realize it, but if they've watched any number of Science Fiction movies and TV shows, they've probably seen parts of the SAGE system. From about 1964 on, parts of the system were used as props in many productions, including Lost In Space, The Time Tunnel, The Man From U.N.C.L.E. and Battlestar Galactica, to name a few. Irwin Allen in particular was fond of the hundreds of blinking lights and switches, and many of his productions used Q7 parts as props. I've been a Science Fiction fan since I could read, and used to watch all the Irwin Allen shows. It wasn't until after I left the Air Force that I realized that the "computers" in the Time Tunnel complex were actually sections of the DMC and SMC from the Q7. Some of these props have been used as recently as 2006, in the ABC production, Lost. I've created another web site with a list of productions with Q7 props, along with screen captures of the equipment: http://ripsaw.cac.psu.edu/~mloewen/Q7/ Mike Loewen USAF 1982-1986 mcl8@psu.edu |

|||

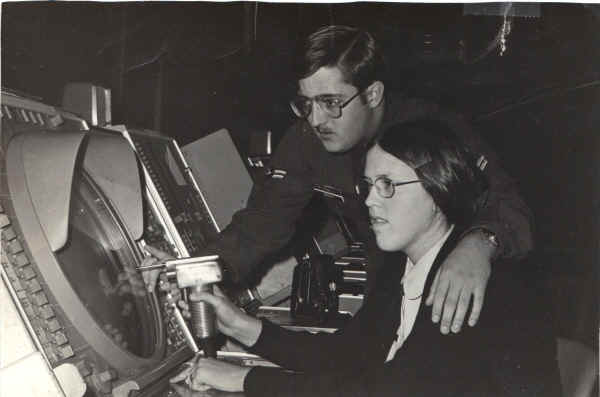

| CPT John P DeWerth's Sage

Memories - This is the first in an ongoing series John will be sharing with us! We were constant having "unknowns" in our sector NYADS. This

was usually

John P DeWerth |

|||

|

Airman First Class Trent Bailey, Weapons Controller Technician at 26th NORAD Region/Air Division

(click SAGE artwork to open in a separate large window)

"Airman First Class

Trent Bailey, Weapons Controller Technician at 26th NORAD Region/Air

Division points out a target for Airman Toni Bailey, a Air Surveillance

Operator new to SAGE Operations, who is also his spouse." Picture was

taken on February 12th, 1975 for an article in the Division's newsletter.

As I recall, there were 3 couples that worked together in the 26th Air

Division and two of them were stationed at the NORAD Region Control Center

at Luke AFB, AZ. Trent Bailey tells us "The 26AD crest is actually printed on adhesive-backed paper and was used to mark manuals, books, etc. I remember a sheet of them had a huge one, like 8X10, then smaller ones, down to an inch high. This is an 3" original from there, and I've had it since my days there. Yellowed with age, it is stuck to a mirror on my workstation at home."

|

|||

|

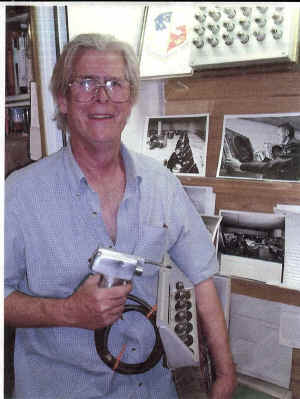

AIR NAVIGATION ATTACK COMPUTER TYPE CPU-73A/P

Trent Bailey tells us: "Ed, it was a mechanical Attack Computer

that enabled Weapons Controllers to calculate intercept vectors for

engaging enemy aircraft. |

|||

|

For BUIC, The SAGE Backup Please see the

BUIC section under Burroughs Click

---HERE

|

|||